Mona Lopez recently joined GreenWood’s home office accounting team in Greenville, South Carolina where she is responsible for processing the weekly payroll, daily cash management, accounts payable, and accounts receivable. She also handles client billings according to established schedules. Mona brings an extensive background within the financial field that spans accounting workflows for accounts payable, contract labor payment, financial statement preparation, budgeting and cash controls. She has spent the past 25 years in various financial roles in numerous market sectors since earning her Bachelor of Arts degree.

Tag: industrial maintenance

GreenWood Earns R Stamp Recertification

Written on . Posted in Press Releases.

GreenWood has completed a recertification for The National Board of Boiler and Pressure Vessel Inspectors (NBBI) R symbol stamp for the repair and/or alteration of boilers, pressure vessels, and other pressure-retaining items. With this certification, only qualified and certified fabricators will perform alterations and repairs. The R stamp is available only to companies who have successfully completed rigorous weld joint testing and whose QC system covers repairs according to established guidelines. We are proud to have the R stamp certification and affiliation with the NBBI as an ongoing credential of our team’s capabilities.

Rudy Duncan Joins GreenWood, Inc. as Project Site Leader

Written on . Posted in Press Releases.

Rudy Duncan has joined GreenWood as Site Manager at our project location in Carrollton, Georgia. Rudy leads the GreenWood team responsible for executing maintenance best practices that support manufacturing and facility operations through a continuous improvement process centered on world class safety standards. For this leadership role, Rudy brings expertise gained from previous manufacturing responsibilities as Maintenance Supervisor, Project Manager, Program Manager, and Technical Services Supervisor after spending time at Stanley Black & Decker, John Bean Technologies Corporation (JBT), Schwan’s Global Supply Chain, Tyson Foods, and Perdue Farms.

Rudy holds a Bachelor of Science in Project Management from Columbia Southern University as well as an Associates of Applied Science in Technical Studies from Middle Georgia Technical College.

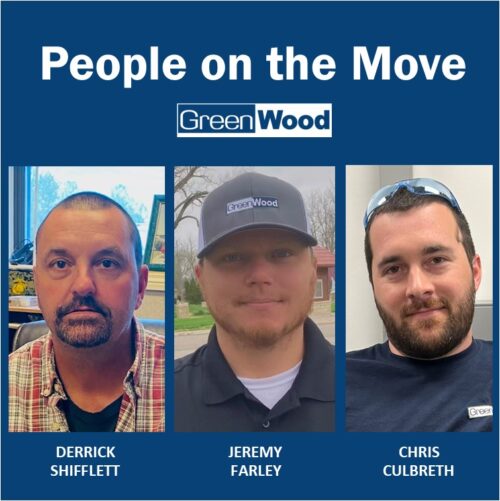

Congratulations to the Following Who are On the Move at GreenWood

Written on . Posted in Press Releases.

We are pleased to announce several individuals at GreenWood who have been appointed to site leadership roles at projects across the U.S. Derrick Shifflett is now Site Manager at our project in Elkton, Virginia. Jeremy Farley has re-located to Emporia, Kansas to lead our project there as Site Leader. In the Greenville, SC area (Piedmont), Chris Culbreth has been named Site Leader to lead the maintenance team at this project. Congratulations to these new leaders at Team GreenWood!

Trent Bailey Named Site Manager

Written on . Posted in Press Releases.

Trent Bailey has been named Site Manager at our project location in Augusta, Georgia. His background includes several years in industrial maintenance as a technician, planner/scheduler, and then supervisor. Trent was a logistics specialist in the Army and earned a bachelor’s degree in project management from Colorado Tech University. Originally from Illinois, Trent and his family moved to the South in 2016 and they love it!

Continuous Improvement Requires a Proactive Maintenance Approach

Written on . Posted in Press Releases.

Maintenance should be a constantly improving activity, which enhances the quality of service, streamlines processes and optimizes operating costs. A continuous improvement environment includes the necessary elements to assess situations and determine improvement opportunities through the application of the following:

• Defining maintenance processes and how critical equipment will be maintained with a focus on failure modes for critical components

– Every maintenance task needs to be directly aimed at creating the best “value” from the assets.

• Assessing the available resources and required tools necessary for proactive maintenance jobs

– Work needs to be executed efficiently and effectively which requires a meticulous work management process to prevent wasteful reworks.

• Establishment of overall objectives with KPI’s for progress checkpoints

– The development and implementation of a ‘balanced scorecard’ of Key Performance Indicators (KPIs) and the support and communication from management are the keys to delivering improvement.

• Integrating the process into a maintenance management system to capture all data points, track activity, and provide reporting analysis

– All data points related to equipment, critical assets, work orders, backlog, labor/man hours, costs, PM schedules, spare parts and more should be monitored and measured to identify where improvements have been made and where they are needed.

Expect the Unexpected

Planning and scheduling is an important element that contributes to maintenance productivity and continuous improvement. However, unexpected failures will occur and disrupt the completion of planned and scheduled work. With this in mind, increased planned work that is focused on eliminating defects (the causes of unplanned work) will result in efficiency gains.

It Continues – as it Should

Ongoing improvement means it continues without ending. The maintenance process requires regular reviews, modifications and adjustments when things change. Taking this approach to continuous improvement will increase uptime and throughput, reduce safety incidents, increase equipment reliability and planned maintenance work resulting in lower maintenance and operating costs.

Cam Clendenin Promoted to Site Manager

Written on . Posted in Press Releases.

We are pleased to announce that Cam Clendenin has been promoted to the role of Site Manager at WVO in South Charleston, West Virginia. GreenWood has maintained a presence at this location for nearly 20 years while supporting multiple clients in the chemical, petro-chemical, and automotive markets.

As Site Manager, Cam is responsible for managing the day-to-day job assignments and personnel resourcing for the project team. Cam oversees the project’s site supervisors and implements best safety practices to ensure work requests are completed safely and efficiently. Additionally, he oversees the NCCER Craft Training Program throughout multiple job sites within the South Charleston area. Prior to this appointment, Cam served as GreenWood’s maintenance manager at this same project where he leveraged 13 years of industry experience to lead his team. Before joining GreenWood, he served as a scaffolding builder (NCCER Certified) through another contractor where he also honed his insulating

skills. A fun fact is that Cam participated in the Associated Builders & Contractors (ABC) National

Craft Championships in San Diego, CA and finished 3rd in the insulation competition.

Cam is heavily involved in the local community where he is currently serving as Mayor of the Town of Eleanor after having served as Town Councilman. He is also a former Board Member of the Putnam County Development Authority. Cam studied management at West Virginia University Institute of Technology and earned a Board of Governor’s Associate in Applied Science at BridgeValley Community and Technical College.

Kevin Crittendon Named President of GreenWood, Inc.

Written on . Posted in Press Releases.

We are pleased to announce that Kevin Crittendon has been named President of the company. In this key leadership role, Kevin is responsible for leading the management team and for all company operations.

Prior to this appointment, Kevin served in various roles within GreenWood as Vice President; Director of Continuous Improvement; and as a Project Manager. His more than 30 years of manufacturing-related experience across multiple business functions and numerous process improvement initiatives have resulted in reduced cost, improved quality, increased throughput, and improved delivery. He has extensive maintenance and operations experience gained from involvement on both the client and company side of the industrial maintenance and operations business. This background along with his experience within GreenWood make Kevin a natural fit for this leadership role.

“Kevin is a results-focused leader who understands how to connect with our team members throughout the company,” says Laura Lipscomb, CEO of GreenWood. “This is an important characteristic because people are the core of our business and delivering the results our clients expect requires someone of Kevin’s caliber to lead the way. His personalized and strategic approach to business will serve us and our clients well. GreenWood is privileged to have him in this important role.”

Kevin holds a Master of Arts in Executive Leadership earned from Liberty University and an undergraduate Bachelor of Science in Business Administration and Management earned from the University of Phoenix. He also has certifications for AMP – Association Asset Management Professional; CMRP – Certified Maintenance Reliability Professional; and PMP – Project Management Professional. Kevin was formerly Vice Chair of the Carolinas Chapter for the Society of Maintenance and Reliability Professionals (SMRP).

GreenWood, Inc. Promotes Three to Project Site Manager Positions

Written on . Posted in Press Releases.

GreenWood, Inc. announces the promotion of Gary Bennett, Robbie Baxley and Tony Boswell as Project Site Managers for the company. Gary Bennett moves to a project site in Augusta, Georgia; Robbie Baxley is managing the GreenWood team at a project facility in Athens, Georgia; and Tony Boswell has been appointed Site Manager at a project location in Hodges, South Carolina. GreenWood is responsible for production and facilities maintenance, as well as supporting other operational services across the three locations. All three of the GreenWood site managers bring extensive maintenance leadership experience gained from various industrial manufacturing and facility environments.

Gary Bennett moves into his role after serving as the GreenWood Site Manager at a project in Athens, Georgia. He has extensive training in management, mechanical, electrical, and fluids. Gary holds a Six Sigma Black Belt Certification and has completed ISO 9001 Quality Management System Lead Auditor and Implementation Training from Lloyd’s Registry.

Robbie Baxley previously served in multiple maintenance roles at the project site in Athens as special projects coordinator, planner/scheduler, and with the team of maintenance technicians. His background includes numerous maintenance supervision, management, and plant operations responsibilities involving facility equipment maintenance, preventive and outage maintenance scheduling, spare parts inventory, safety, and technical training.

Tony Boswell is now the site manager at GreenWood’s project location in Hodges, South Carolina where he previously served as Maintenance Supervisor. Tony brings maintenance proficiency and leadership experience to this role gained from problem solving, maximizing productivity, minimizing manufacturing costs, and identifying areas of improvement. He holds an Associate’s Degree in Industrial Electrical Technology and has advanced skills in Mechanical, Electrical, and Plumbing (MEP) with additional experience with Machine Tools and CNC Operation.

- 1

- 2